Product Optimization

Intact Breast Lesion Excision System

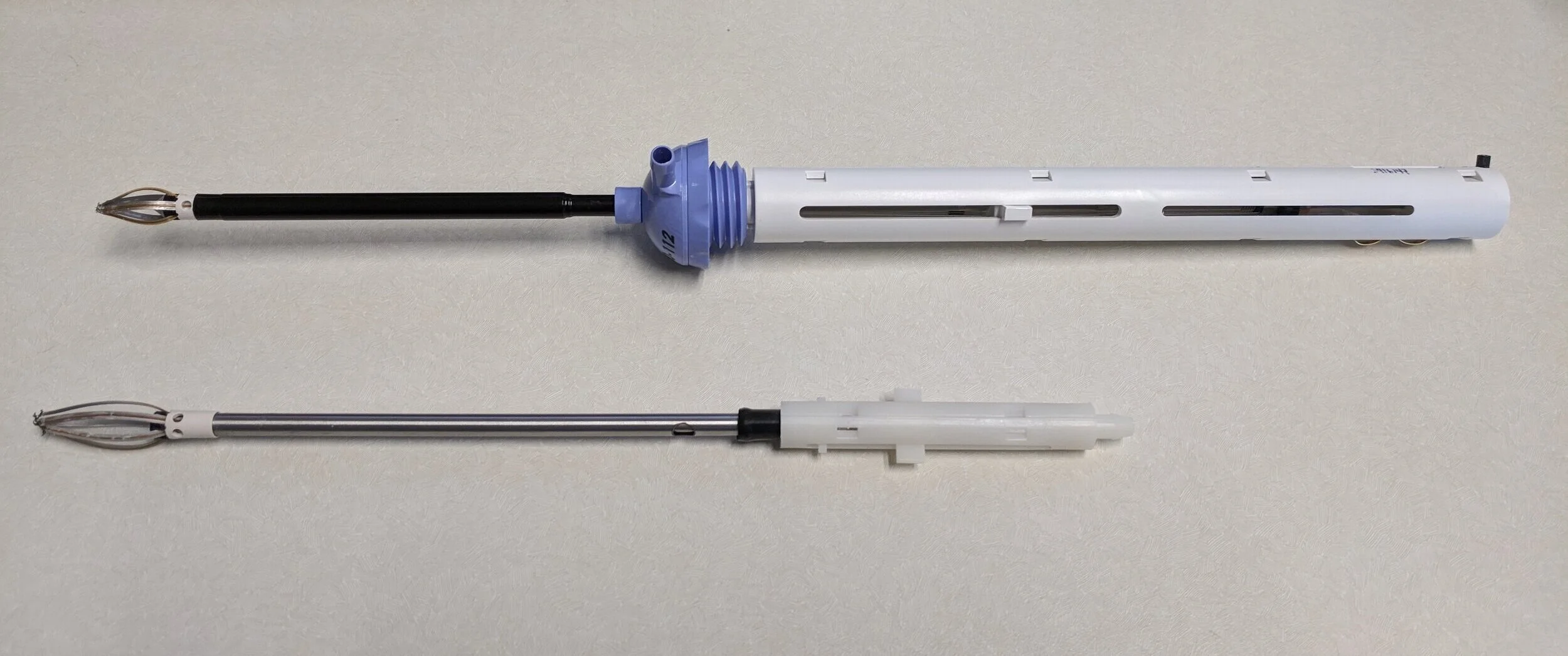

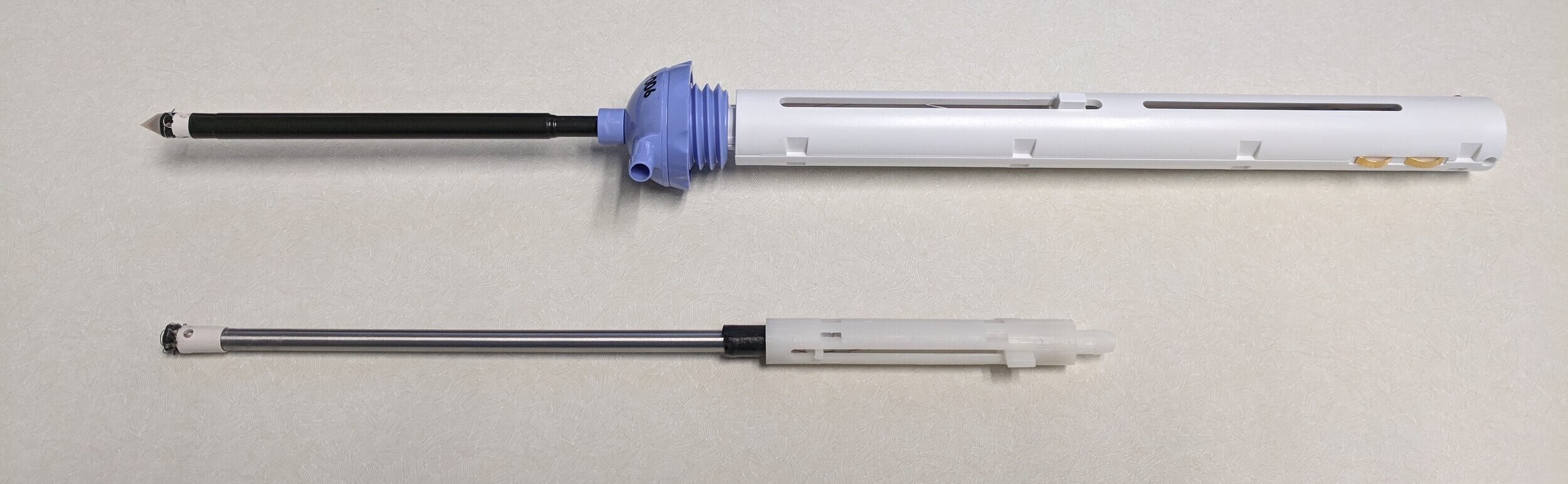

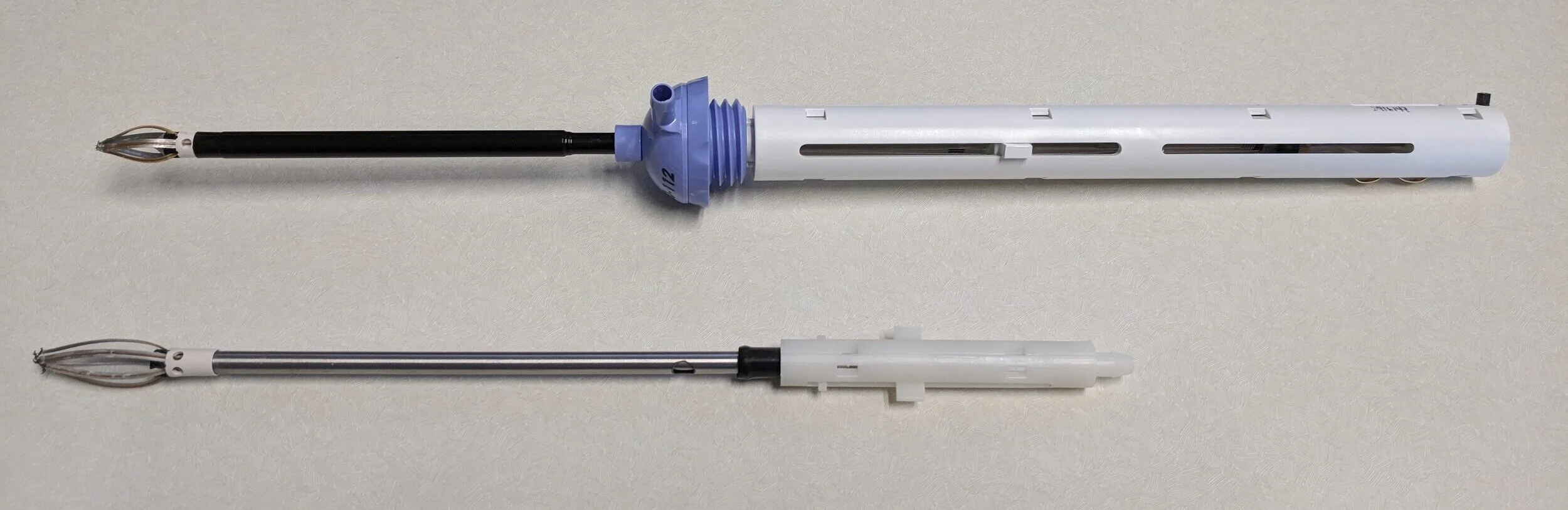

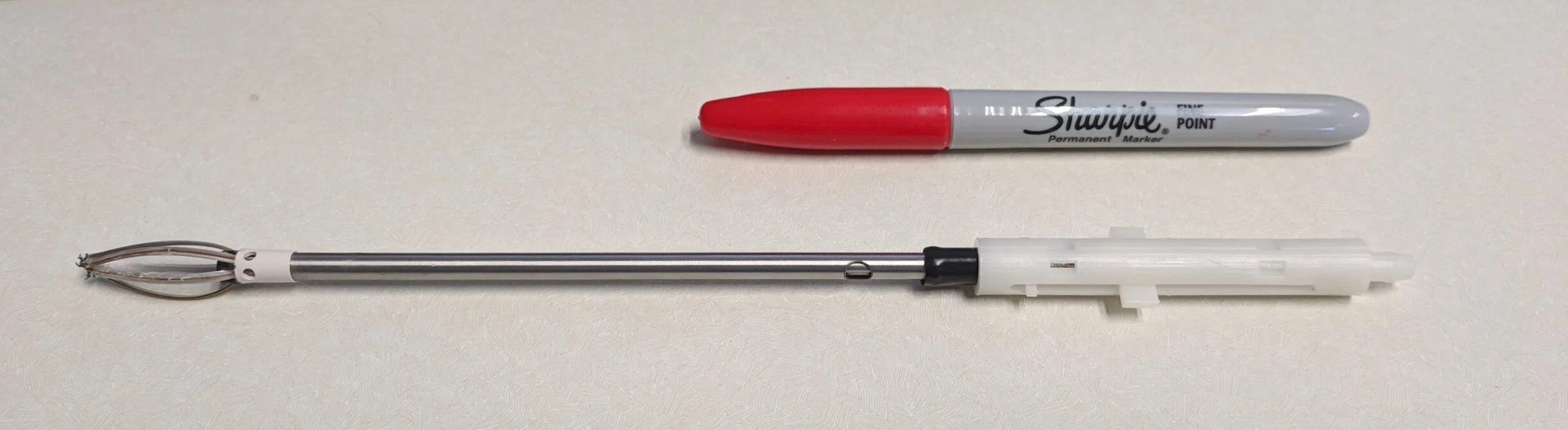

Lesion Excision System consisted of a disposable, reusable, and capital generator, designed to capture large tissue samples for both diagnostic and tumor excision purposes. The existing product struggled with cost, usability and reliability. Responsible for targeting usability pain points and aspects of reliability.

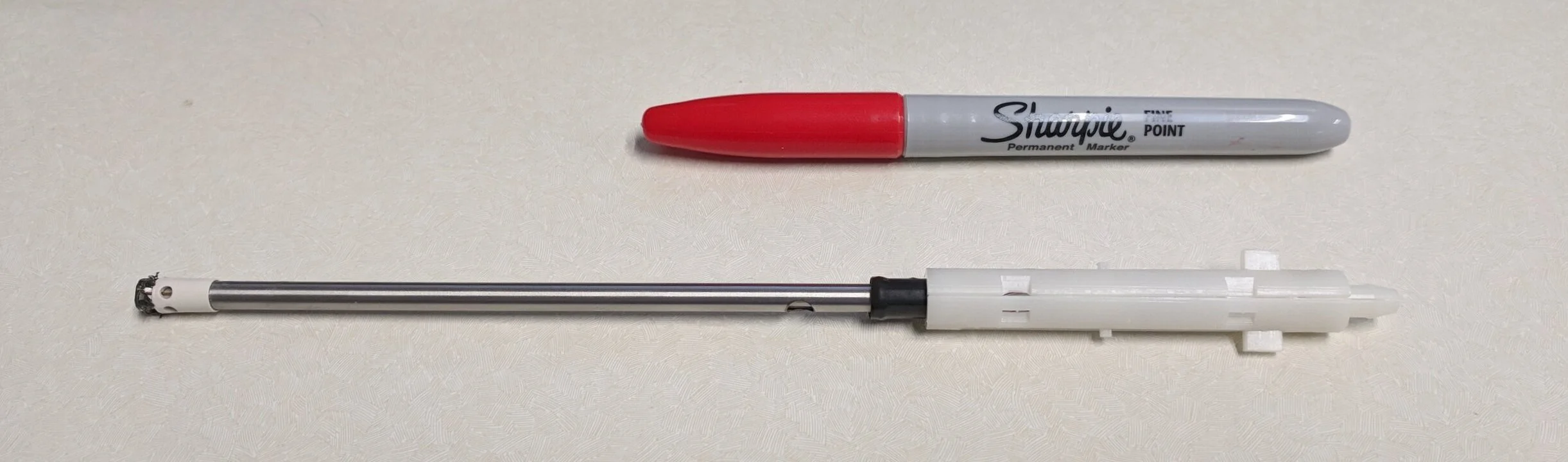

From usability perspective, the existing disposables component was bulky and unwieldy. Under the design requirement of the same drive mechanism, a new disposable was designed and prototyped. The optimized component resulted in a total volume reduction of 87% from the previous generation.

In addition, it provided confidence in the future generations size assumptions. I was able to confidently manage and collaborate with human factors specialists to propose alternative system designs based on the confidence in size assumptions.

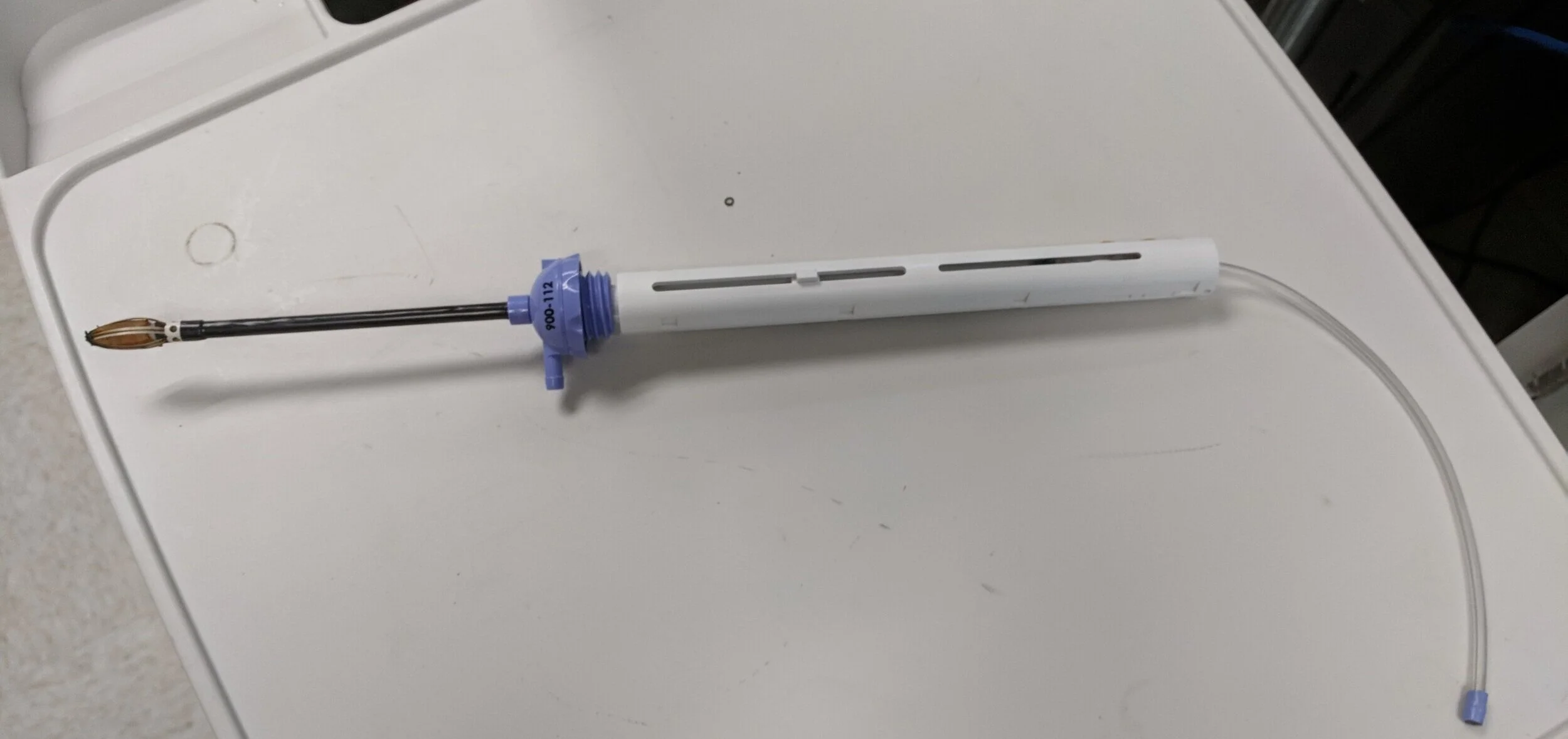

Shaft Temperature Reduction

A constant concern of RF ablation is surgical smoke generation. This smoke generates unnecessary heat at the surgical site and is toxic to surgical staff. The previous generation of the product struggled with smoke evacuation and shaft temperature was measured at 190°F. I was tasked with reduction of shaft temperature and diameter.

Collected data on existing product to identify root cause of shaft temperature. Once insufficient suction was identified, two primary designs were considered.

Both opted for an axial suction pathway compared to the prior generation which exited perpendicular to the suction pathway. The primary prototype measured at 70°F, resulting in a 60% reduction in temperature. In addition, the shaft diameter was reduced by 20%. The exploration was a success in showing that further optimization was possible. While 60% reduction in temperature and 20% in diameter is a win, design optimization could result in even further reduction.